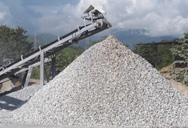

Prix concassage de pierres unité POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- broyeurs à ciment aman ltd

- vs osha qui est en faute ici

- utilis broyeurs de charbon vendre

- mini fraiseuse prix de malaisie

- broyeur de pierres criteriya

- prix mini concasseur de roches canada

- britagem e peneiramento precos

- rupture de l ngrenage des anneaux

- machine doccasionn de recyclage des pneux

- les navires tronsporteurs des passages

- etud de calcul sur les broyeur a marteaux pdf

- eficiente de la primavera chancadora de cono

- laitier concasseur ludhiana vegetale inde

- séparateurs de minerai de fer brésilien

- ball mill avantages

broyeur de pierres cout du projet

Ball Mill Grinding Machines: Working Principle, Types, Parts ...

Advantages of Ball Mill. Ball mill grinding machine offer several advantages, including: Versatility: Ball mills can perform various types of grinding, such as dry grinding ball mill or wet grid ball mill, batch or continuous grinding, and fine or ultra-fine grinding, making them suitable for a wide

Read More

球磨机的 4 大优缺点是什么? - Kintek Solution

球磨机的 4 大优势. 1.研磨效率高、粒度细. 球磨机可以将物料研磨到非常细的粒度,通常小于或等于 10 微米。 因此,球磨机非常适合需要高精度和精细研磨的应用。 2.多功能性和广泛的应用范围. 这些研磨机可处理各种材料,包括磨料和有

Read More

Advantages and Disadvantages of Ball Mill - AspiringYouths

Advantages of Ball Mill. Handles a variety of materials – Ball mills are versatile, capable of processing different types of materials, from hard solids to highly reactive chemicals. Low

Read More

What are the advantages and disadvantages of ball mills

2024.11.5 Advantages of ball mills compared to other types of grinders: 1. Versatility in grinding methods: Wet and dry grinding capabilities: Ball mills can handle both wet and dry

Read More

了解实验室和工业应用中球磨机的优缺点 - Kintek Solution

了解实验室和工业应用中球磨机的优缺点. 球磨机是实验室和工业环境中研磨材料的基本设备。. 在本文中,我们将探讨使用球磨机降低粒度和混合材料的优缺点。. 我们还将讨论球磨机的多功

Read More

Ball Mill: Operating principles, components, Uses, Advantages

2022.11.30 Advantages of Ball Mills. 1. It produces very fine powder (particle size less than or equal to 10 microns). 2. It is suitable for milling toxic materials since it can be used in a

Read More

Advantages and Disadvantages of Ball Milling Process

Advantages of Ball Milling Process. Produces uniform particle sizes – Ball milling process ensures particles are all the same size, enhancing consistency in the end product. This uniformity in

Read More

Ball Mills working principle advantages - Across International

2023.10.27 Advantages of Ball Mill. 1. Produces a very fine powder – particle size less than or equal to 10 microns. 2. Suitable for milling toxic materials. 3. A wide range of

Read More

Introduction to High-Energy Ball Mill: Working Principle, Advantages ...

2022.3.30 In this blog we share an overview of Ball Mill, how it works, its advantages and features. When people think about milling machines, they will come across vertically oriented

Read More

Advantages of Ball Milling - Powder Bulk Solids

2016.7.13 Ball mills have a number of advantages for milling solids either wet or dry. In order to minimize product contamination, ball mills can be constructed with a wide range of

Read More

Advantages of Ball Milling - Powder Bulk Solids

2016.7.13 Ball mills have a number of advantages for milling solids either wet or dry. In order to minimize product contamination, ball mills can be constructed with a wide range of materials including abrasion-resistant high-chrome steel, alumina brick, and cast polyurethane.

Read More

Ball Mill Working Principle, Construction, Applications, Advantages

5 天之前 Ball mills produce 1 to 50 ton/h power of which about 70 to 90 percent would pass a 200 mesh screen and the energy requirement of a ball mill is about 16 kWh/t. In the case of the batch-operated mill, a measured quality of a solid to be ground is charged into the mill through an opening in the shell.

Read More

Ball Mill - SpringerLink

2023.4.30 Ball mill is a type of grinding equipment that uses the rotary cylinder to bring the grinding medium and materials to a certain height and make them squeeze, impact, and grind and peel each other to grind materials. Ball mill is the key equipment for crushing materials after they are crushed. It is widely used in cement, silicate products, new ...

Read More

Balls for ballmills : Alpha Grinding Media

2024.4.26 The ball mill is an efficient grinding apparatus commonly utilized in the fields of mineral processing, construction materials, and chemical manufacturing. ... Ball Mill Advantages – Operates continuously with a high processing capacity – Efficient usage and

Read More

Ball Mill - Principle, Construction, Working, and More - Soln

6 天之前 Ball mills are also used in the manufacture of black powder. The blending of explosives is an example of an application for rubber balls. For systems with multiple components, ball milling is effective in increasing solid-state chemical reactivity. Ball milling has been shown effective for the production of amorphous materials. Advantages of ...

Read More

Ball Mill Success: A Step-by-Step Guide to Choosing the

2024.8.8 Unlock the secrets to ball mill efficiency with our comprehensive guide on choosing the right grinding media. Learn how material composition, size, shape, hardness, and cost impact your milling process and outcomes. ... each offering unique characteristics and advantages tailored to specific applications. Ceramic Balls: Composed of materials ...

Read More

Vertical roller mill vs. ball mill for cement grinding:

A ball mill is a traditional grinding machine that has been used in the cement industry for decades. It consists of a rotating cylinder filled with steel balls that crush and grind the material as the cylinder rotates. Ball mills are known for their reliability and ability to grind materials to a fine consistency. Advantages of Ball Mills:

Read More

(PDF) Grinding in Ball Mills: Modeling and Process Control

2012.6.1 approach is most frequently used in ball mill grinding circuits. The main advantage . ... Ball mills can grind a wide range of materials, including metals, ceramics, and polymers, and can operate ...

Read More

Ball milling: a green technology for the preparation and ...

The ball mill Ball milling is a mechanical technique widely used to grind powders into fine particles and blend materials. 18 Being an environmentally-friendly, cost-effective technique, it has found wide application in industry all over the world. Since this mini-review mainly focuses on the conditions applied for the preparation and ...

Read More

Ball Mills - 911Metallurgist

2017.2.13 Ball Mills or Rod Mills in a complete range of sizes up to 10′ diameter x 20′ long, offer features of operation and convertibility to meet your exact needs. They may be used for pulverizing and either wet or dry grinding systems. ... Thus the Marcy Mill has the advantage in cases where the lowest possible discharge level is required ...

Read More

What are the Advantages of Wet Ball Milling?

Wet ball milling offers several advantages over dry ball milling, including improved grinding efficiency, reduced risk of contamination, and easy scalability. Skip to content ... Wet ball milling is a method of grinding particles in liquids using a ball mill. In recent years, this technique has gained popularity due to its simplicity ...

Read More

What Is a Ball Mill and How Does It Work? (Overview 2024)

2024.7.12 The cylindrical shell, for conical mills, for instance, houses the grinding media and the material being processed. The ball mill rotates around a horizontal axis, allowing the grinding process to take place as the balls reduce the material to a fine powder. ... suit scientific research and material synthesis well, offering several advantages ...

Read More

Understanding the Advantages and Disadvantages of Ball Mills

Ball mills have several advantages and potential benefits that make them highly suitable for various applications across different industries. Advantages of Ball Mills. High Grinding Efficiency: Ball mills are capable of achieving rapid grinding of materials, particularly those with high hardness and viscosity. Their high grinding efficiency ...

Read More

Ball Mill; Principle, Working, and Construction » Pharmaguddu

2022.10.17 Normal speed: At Normal speed balls are carried almost to the top of the mill and then fall into a cascade across the diameter of the mill, in this way maximum size reduction is obtained. Related: Hammer Mill. Ball mill usage in Pharmaceuticals: It is used in reducing the size of the drug. Advantage: Minimum loss of materials

Read More

Ball Milling - an overview ScienceDirect Topics

Ball milling technique, using mechanical alloying and mechanical milling approaches were proposed to the word wide in the 8th decade of the last century for preparing a wide spectrum of powder materials and their alloys. In fact, ball milling process is not new and dates back to more than 150 years. It has been used in size comminutions of ore, mineral dressing, preparing talc

Read More

Ball mill – Working and Its Advantages - acmasindia

2014.4.17 Ball mill works on impact principle that is size reduction is done by the impact. It contains a hollow cylinder shell that rotates around its axis and is partially filled with the balls.The ball mill may be operated in a batch or continuous fashion and wet or dry.. In case of continuously operated ball mill, the material to be ground is fed from the left through a 60 degree cone and

Read More

Advantages and Disadvantages of Ball Milling Process

Advantages of Ball Milling Process. Produces uniform particle sizes – Ball milling process ensures particles are all the same size, enhancing consistency in the end product. This uniformity in size helps in maintaining quality control. Low operation cost – It is also a cost-effective operation. The cost of running and maintaining the equipment is low, making it a budget-friendly choice.

Read More

Ball Mill Principle, Construction, Uses, Advantage ... - Gpatindia

2021.8.17 A. Hardinge mill, the variant of ball mill consist of a hollow cylinder with conical end B. Rods and bars can also be used in place of balls as grinding medium in ball mill C. Ball mill is an open system, hence sterility is a question D. Fibrous materials cannot be milled by ball mill. 10. What particle size can be obtained through ball mill?

Read More

Types of Mill Explained Ablison

2024.8.13 Ball mills are widely used in industries requiring fine grinding of materials, particularly in mineral processing, cement, and ceramics. They consist of a rotating drum filled with steel or ceramic balls that grind the material as it tumbles. ... Vertical Mill Advantages. Vertical mills, also known as vertical roller mills (VRMs), are ...

Read More

Rod Mill VS Ball Mill: Which is Best for Your Project?

2024.10.29 2). **Lower Capacity**: Rod mills generally have a lower throughput compared to ball mills, which can be a limiting factor for larger projects. 3). **Higher Initial Cost**: The initial investment for rod mills can be higher than that of ball mills, which may deter some project managers. 3. Advantages of Ball Mills. 1).

Read More