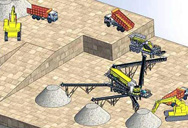

processus de placoplâtre POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- concasseur calcaire utilisé

- usa fournisseurs de plantes de concassage

- concasseur Indonésie percussion willam

- secteur du concassage de pierres dans l'Uttarakhand

- broyeur a billes horizontal pour les fines de minerai de fer

- Concasseur Hsi Calcaire

- jc2236 pièces de rechange de concasseurs a machoires

- coût de la machine de requête de pierre

- concasseur de carriere de blonde

- fabricantes de trituradoras de piedra en bolivia

- mâchoire concasseur fabricants en amérique du nord

- prix de la mchoire mobile et de la plaque à bascule

- ballast usine de concasseur Indonésie vendre

- concasseur a percussion pe900x1200

- metal ore crush and grind

broyeur de pierres cout du projet

Ore Grinding - SpringerLink

2023.7.20 Ore grinding is a process to further reduce and disperse the ore particle size. In the mineral processing industry, ore grinding is the particle size preparation before the

Read More

Metal Ore Extraction and Processing - Springer

2017.8.23 In modern metal ore extraction, the most common technique is open-pit mining. In much the same manner as open-pit coal extraction, soils and vegetation are removed from

Read More

Energy Use of Fine Grinding in Mineral Processing

2013.12.18 Abstract. Fine grinding, to P80 sizes as low as 7 μ m, is becoming increasingly important as mines treat ores with smaller liberation sizes. This grinding is typically done using

Read More

Mining Balls: The Backbone of Material Processing

2023.10.4 Grinding balls, steel grinding balls, forged steel grinding balls, and rolled grinding balls are integral components in mining operations. They are used in ball mills to

Read More

Crushing Mineral Processing - 911Metallurgist

2016.1.17 In mineral processing, the reduction of minerals by crushing and grinding may be regarded as having one or other of two main objectives: the attainment of a size

Read More

Introduction to Mineral Processing or Beneficiation - Sepro

In order to separate the minerals from gangue (the waste minerals), it is necessary to crush and grind the rock to unlock, or liberate, valuable minerals so that they are partially or fully

Read More

Comminution and classification technologies of iron ore

2022.1.1 Most of the high-grade hematite iron ores are typically subjected to simple dry processes of crushing and classification to meet the size specifications required for direct

Read More

Development of ore sorting and its impact on mineral processing ...

2014.10.15 The goal of ore sorting is to reduce the total amount of material sent to the high energy milling circuit, while not significantly impacting total metal recovery. In general, ore

Read More

Difference between Crushing and Grinding - 911Metallurgist

2017.2.17 Difference between Crushing and Grinding - 911Metallurgist. When making comparisons of the efficiencies of different grinding and crushing machines it is desirable to be

Read More

Forged Steel Grinding Balls by ENERGOSTEEL

2024.5.7 Forged steel grinding balls are primarily used in ball mills or rod mills to crush and grind materials into finer particles. In the mining industry, they are used to extract precious metals from ore. Cement manufacturing utilizes these balls to grind clinker, limestone, and other materials into a fine powder, a crucial step in the production ...

Read More

Types of Crushers: Choosing the Right One for

2024.7.17 Jaw crushers use the compressive and bending action of a fixed jaw plate and a movable jaw plate to crush materials of various hardnesses. When the two jaw plates come together, the material is crushed; when the

Read More

Metal Ore Extraction and Processing - Springer

2017.8.23 In modern metal ore extraction, the most common technique is open-pit mining. In much the same manner as open-pit coal extraction, soils and vegetation are first ... Oxide ore Crush Grind Leach Calcine Electrolysis Fe Sulfide ore Crush Grind Sinter or Pelletize Blast Furnace Steel Making Direct Reduce Pb Sulfide ore Roast Sinter Blast Furnace ...

Read More

How to grind rock gold ore into fine powder? - LinkedIn

2023.4.3 As the drum rotates, the balls crush and grind the ore into a powder. 3.Separating the Gold: Once the ore has been ground into a fine powder, it needs to be separated from the other minerals in ...

Read More

8 Types of Gold Ore - Properties and Ways to Process

2023.6.12 1 Crush, grind, and classify the raw oxidized gold ore (containing copper). 2 Give the ore an alkaline treatment. 3 Add certain proportion of chelating agent and sodium cyanide to inhibit the leaching of copper and the selective leaching of gold.

Read More

How it Works: Crushers, Grinding Mills and Pulverizers

2017.6.2 Table Source: Wikipedia (Crushers) Cone crushers use a spinning cone that gyrates in the bowl in an eccentric motion to crush the rock between the cone surface, referred to as the mantle, and the crusher bowl liner.Gyratory crushers are very similar to cone crushers, but have a steeper cone slope and a concave bowl surface. As the gap between the bowl liner

Read More

12.3: Metals and Ores - Chemistry LibreTexts

Mild steel: Mild steel is iron containing up to about 0.25% of carbon. The presence of the carbon makes the steel stronger and harder than pure iron. The higher the percentage of carbon, the harder the steel becomes. Mild steel is used for lots of things - nails, wire, car bodies, ship building, girders and bridges amongst others.

Read More

nigeria aluminium ore crushers and grinding mills - LinkedIn

2023.9.25 Ball Mill: Ball mills are commonly used for grinding aluminum ore into a fine powder. They consist of a rotating cylinder filled with grinding media, such as steel balls, which crush and grind the ...

Read More

Titanium Ore Crushing and Grinding Machine - Liming

2023.10.10 The machine uses grinding media, such as balls or rods, to crush and grind the ore into a fine powder. The grinding action helps to separate the titanium minerals from impurities. Milling Options: Ball Mills: Suitable for dry or wet grinding,

Read More

Gold Refinery Process: From Raw Material to Pure Gold

The crushed ore is transferred to a grinding mill, which contains heavy-duty steel balls or rods. As the mill rotates, the balls or rods crush and grind the ore, resulting in the formation of a fine powder. The purpose of crushing and grinding the gold ore is to liberate the valuable gold particles from the surrounding rock and minerals.

Read More

Kenya metal ore grinding mills machine - LinkedIn

2023.9.21 As the mill rotates, the grinding media crush and grind the ore into finer particles. Rod Mills: Rod mills are similar to ball mills but use long rods as grinding media instead of balls.

Read More

Assessing composition and compatibility of ore grinding balls

Imasco Minerals had an opportunity to buy several hundred steel balls used to crush and grind ore in a ball mill. But the company needed to have accurate and detailed information about the composition of the steel balls to assess whether these would be compatible with its existing ball milling equipment. Imasco quality assurance manager David ...

Read More

Eco-efficient and cost-effective process design for magnetite iron ore ...

There have been three expansions since and, in the 1990s, Empire Mines had a total of 24 individual concentration lines and a total plant capacity of 8 Mtpa of pellets. The target grind size of the circuit varies between the 90-95 percent minus 500 mesh (32 μm) depending on the ore and operating conditions (Rajala et al., 2007).

Read More

How To Make Steel In Mortal Online 2 - Loot and Level

2024.7.14 Once you have all of the ores, it’s time to start refining all of them down into steel. Here is the process: Crush Granum in the crusher outside of town – to obtain blood ore. Grind Saburra in the grinder outside of town – to obtain Saburra power Crush Calx in the crusher outside of town – to obtain Calx power and coal. Extract Coal in a furnace to make Coke.

Read More

A Brief - Reclaim, Recycle, and Sell your Precious Metal Scrap

2014.2.21 As one of America’s best gold refiners, Specialty Metals can recycle your gold-bearing scrap and turn it into real gold – and real profits – for your company. Contact us at 800-426-2344 to learn more today. Related Posts. The Confusing –

Read More

id/metal ore crush and grind.md at main luoruoping/id

Contribute to luoruoping/id development by creating an account on GitHub.

Read More

Types of Crushers Explained: Everything You Need to Know

2024.4.19 This method is popularly employed in fine grinding processes such as ball mills or rod mills. In these mills, the material is blended with grinding media, for instance, balls or rods made of steel. The rotation of the mill makes the media grind and wear out the material, thus lowering its size in stages.

Read More

Ore Grinding - SpringerLink

2023.7.20 Except those that process some placers, almost all mineral processing plants have grinding operations, in which materials are crushed by the impact and abrasive action of grinding medium (steel rod, steel ball, gravel, or ore block itself) to meet the requirements of separation operation, and the particle size of the product is generally less ...

Read More

What Is a Ball Mill and How Does It Work? (Overview 2024)

2024.7.12 We commonly use ball mills to crush and grind materials into an extremely fine form. They serve both dry and wet milling purposes and are often constructed out of cast iron. Various industries, including cement , silicate, new building materials, refractory, fertilizer, black and non-ferrous metals, and glass ceramics, use ball mills.

Read More

Crushing in Mineral Processing - 911Metallurgist

2015.12.26 In mineral processing or metallurgy, the first stage of comminution is crushing.. Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks. In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wear-resistant plate/surface.

Read More