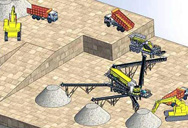

rouleaux a cylindre moulins POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- le marbre de fer de broyage fournisseurs de broyeurs à boulets

- Australies et services de broyage

- proceso de la producción minera de manganeso

- cisco inde taux de broyeur de pierres

- fournisseurs de minerai de fer utilise broyeur a boulets

- specifications de la machine concasseur de pierres

- Le broyeur Indonésie boulets rpm

- Mesin broyage Makalah

- jhansi Afrique concasseur de pierre

- les horaires de la priere de moulins la marche

- fabricants de balustrade en fer forge fenêtre

- ancien moulin de Raymond annee de fonctionnement

- station concassage d'masse volumique

- broyeur agrimaster kn 2m80

- Afrique concasseur de pierre de sable de silice caractérisation

broyeur de pierres cout du projet

Afrique concasseur de pierre estimée - prospexion

2024.4.2 CONCASSEUR DE PIERRE : Nous serions à la recherche d'un broyeur capable de déchiqueter des bobines de papier jusqu'à 1. 2m de diamètre, avec différente typologie de

Read More

nigeria Afrique concasseur de pierre usine - prospexion

2024.7.4 Prix de la machine de concassage de pierre en afrique . agrega de 4/25mm . Voir plus; pierre concassée nigeria limited. 2020.8.24 Un concasseur sert à transformer des blocs

Read More

Afrique concasseur de pierre 0731 - iiidesign

Description du traitement de la silice, de sa propriété minérale géologique à la manière d'extraire le minéral de la roche et du gisement placérien, diagramme de flux de l'usine de traitement et

Read More

concasseur de pierre de sable de silice - les-frenes

Cette installation est destinée au traitement du sable de silice, la taille du sable de silice étant comprise entre 0 et 10 mm. Trémie + alimentateur électromagnétique > convoyeur à bande >

Read More

concasseur de pierre pour la fabrication de sable sud-africain

L'ensemble de la ligne de production de sable d'AIMIX se compose de nombreuses pièces, dont la plus lmentaire comprend un alimentateur vibrant, un concasseur choires, un concasseur

Read More

Fabricants de sable de silice Afrique du Sud - arkadel

Découvrez aujourd'hui notre vaste gamme de concasseurs à mâchoire, de concasseurs à cône ou à impact dont la robustesse et la fiabilité sont inégalées. Read More ncasseur à cône

Read More

Les carrières et sociétés de concassage d'Afrique - Go Africa

GRANUTOGO est une société de concassage d’agrégats spécialisée dans la vente de sable de granite et de graviers concassés. Filiale de Scancem International, membre de

Read More

fabricants de concasseurs de pierre en Afrique du Sud

Agent de concasseur de pierre en Afrique Il y a beaucoup d'agent de concasseur de pierre en Afrique. Le développement de machines de concassage de pierre est très rapide. Les

Read More

concasseur de pierre de sable de silice - mgnat

L'une des utilisations les plus courantes du sable de silice est la filtration de l'eau, qu'il s'agisse de traiter l'eau de puits ou de filtrer votre eau du robinet. En raison de sa forme et de sa taille

Read More

Fabricants De Concasseur De Pierre En Afrique

Agent de concasseur de pierre en Afrique. 2021.1.26 SBM a l’agent de concasseur de pierre en Afrique. Les clients ont largement le choix pour l'quipement de broyage. Parmi ces

Read More

Etude des caractéristiques physico-mécaniques des bétons de sable

2014.4.1 Etude des caractéristiques physico-mécaniques des bétons de sable à base de fumée de silice.pdf

Read More

Valorisation des sables de fonderie - Climaxion

2021.5.12 Les déchets de sable concernent les fonderies qui mettent en œuvre des procédés de moulage et de noyautage à base de sable. Ces déchets de sable, composés de grains réfractaires (généralement siliceux) et d’un liant (argileux ou à prise ... une étude de caractérisation et de débouchés a été réalisée par le cabinet IES ...

Read More

Concasseur a mâchoire - concasseur de pierre

Concasseur a mâchoire - OTT Globale Un concasseur a mâchoire est une machine conçue pour réduire les grosses roches en petites pierres, graviers, ou poussières de roche. Les concasseurs a mâchoire de la société OTT Globale peuvent être utilisés pour réduire la taille ou changer la forme des roches dure afin qu'ils puissent être plus facilement utilisés, éliminés ou recyclés.

Read More

Traitement de la silice - Équipement, flux de processus, cas

2024.11.9 Description du traitement de la silice, de sa propriété minérale géologique à la manière d'extraire le minéral de la roche et du gisement placérien, diagramme de flux de l'usine de traitement et conception de l'agencement. ... Machine de fabrication de sable VSI; Concasseur mobile; Installations mobiles de concassage; Broyeur à ...

Read More

Concasseur mobile prix en Turquie - concasseur de pierre

2023.3.30 concasseur kleemann neuf en Turquie La pertinance du concasseur mobile prix en Afrique. Il y a nombreux de diversité de pierres; Pour tous ces agrégats de mixtes, la même machine ne peut pas être applicable, et par conséquent, il est de choisir vraiment de la bonne qualite. le bon en fonction de vos besoins pratiquement recentis dans tous les decennies.

Read More

concassage de pierre de sable de silice mini - kubus

2024.3.2 vente de machine de concasseur de pierre en du sable cribl convoyeur à bande; chaîne de sud mining usine afrique.sable de fabrication concasseur de briques - fretingtimer l'équipement de sable Concasseur à mâchoires la brique d'argile usine de fabrication en Afrique du Sud; comment faire une machine a brique en argile YouTube.

Read More

concasseur de pierre de sable de silice - les-frenes

Machines à laver le sable de silice. 80-160. 18.5. 4500*3206*3480. JXSC fournit des types de machines de lavage de sable depuis plus de 30 ans, fournit des machines de nettoyage de sable de haute qualité et une conception d'usine en fonction de différentes conditions, expérimenté dans le lavage d'agrégats, le lavage de charbon, le gravier, le sable siliceux, le sable ...

Read More

concasseur de pierre disponible

2023.4.6 concasseur de pierre disponible Alimentateur Vibrant, Broyeur A Cône, Broyeurs A Axe Vertical, Concasseur A Mâchoire, Concasseur A Percussion, Concasseur Primaire, Concasseur Secondaire, Concasseur Tertiaire, Crible Grizzly, Crible Horizontal, Crible Inclinés, Laveur A Battoires, Laveur De Sable A Roue, Vis De Lavage A Sable,

Read More

Formulation, caractérisation des mortiers à base de sable

2024.8.29 Colloque Eau, Déchets et Développement Durable, 28 – 31 mars 2010, Alexandrie, Egypte 281 Formulation, caractérisation des mortiers à base de sable de dune

Read More

Choisir le meilleur sable de filtre de piscine : options de silice, de ...

2024.3.14 Le sable de silice est également abordable et facilement disponible, ce qui en fait un choix populaire parmi les propriétaires de piscine. L’un des principaux avantages du sable siliceux est sa durabilité. Il peut résister à des débits et à des niveaux de pression élevés sans se décomposer ni perdre son efficacité.

Read More

Sable de silice utilisé comme média filtrant sur la filtration de

Le sable de silice est utilisé depuis longtemps pour nettoyer et purifier l’eau. 4 qualités de sable de silice sont principalement utilisées pour la filtration de l’eau dans le monde entier. La première mention de sable de silice remonte à l’année 1804, lorsqu’un homme du nom de John Gibb a pu concevoir et installer un filtre ...

Read More

Caractérisation granulaire et valorisation des sables

2023.10.3 Caractérisation granulaire et valorisation des sables d’altération des massifs granitiques de la carrière d’exploitation artisanale de sable de Nepenet (Bafoussam Cameroun) D’

Read More

Machines à laver le sable de silice - JXSC Machine

5 天之前 Lavage et criblage des sables est la partie la plus importante du processus de fabrication du sable, JXSC vous recommande 3 types d'abrasifs.Machine à laver les sables de silice pour le lavage de sable de silice de différentes tailles.. 1 Rondelle à bûches. La machine à laver les grumes/la machine à laver les sables décape, décompose et nettoie en profondeur

Read More

Fabricant de ligne de production de sable - Zenith-concasseur

2014.7.19 Après le broyage, le sable de silice broyée sera tamisé en différentes qualités par le crible vibrant. Et l’équipements de lavage permet de nettoyer le sable de silice broyée par grades. Le concasseur à mâchoires primaire réduira le sable brut, le sable concassé sera introduit dans l’usine de concassage tertiaire pour le broyage ...

Read More

Caractérisation granulaire et valorisation des sables

2021.1.3 artisanale de sable de Nepenet (Bafoussam Cameroun) ISSN : 2028-9324 Vol. 31 No. 2, Dec. 2020 190 peut les ende adapté au béton de bonne ésistance au détiment de la facilite de mise en œu Àe. Ainsi l’amélioation de la qualité dudit sable réside en la mise en place d’un dispositif de la Àage pemettant de ende ces matéiau plus popes.

Read More

Comment traiter le sable de silice - JXSC Machine

4 天之前 Sable de siliceLe sable siliceux, également connu sous le nom de sable de quartz, est principalement composé de silice (SiO2), qui est la matière première principale pour la fabrication du verre.Le sable siliceux comprend le sable siliceux ordinaire, le sable siliceux raffiné et le sable siliceux de haute pureté. La teneur en silice du sable de silice ordinaire est comprise entre

Read More

(PDF) Les 3emes journées de valorisation de la silice et des

Les analyse avec DRX montre que 99% de sable de ouargla est du quartz (SiO2) avec une légère quantité de calcite (CaCO 3), pour les autres échantillons 55% du quartz et 40% calcite. Pour les roses de sables le composé principal est le gypse (CaSO 4) mais avec une concentration plus importantes dans les échantillons d’Adrar.

Read More

Usine de traitement de sable de silice - Machine JXSC

2024.11.9 1.3 Formes minérales existantes. Le quartz : Le principal minéral porteur de SiO 2 est également le minéral principal de la recherche expérimentale. Sa forme et sa forme d'encastrement sont simples. Les formes de sortie du minerai sont principalement les suivantes : (1) Sable : copeaux subcirculaires-sous-anguleux, bon tri, support de particules, cimentation

Read More

Concasseur de pierre à vendre concasseur mobile fixe

Concasseur de pierre à vendre en TURQUIE.Types de concasseur à vendre: concasseur mobile; concasseur a machoire; concasseur à percussion; concasseur pierre; concasseur beton; concasseur carrière. Un concasseur est une machine de concassage conçue pour réduire les grosses roches en petites pierres, gravier, ou poussière de roche.. Les concasseurs peuvent

Read More