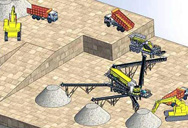

l efficacité de Raymond moulin POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- broyeur de mchoires usagé andhra pradesh

- kaolin mobiles reparation de concasseur en afrique du sud

- rapport de lunité de broyage de chaux projet

- traitement moulin minerale

- mâchoire dynamique concasseur

- courte tête printemps concasseur Indonésie cône

- expansion machines de process le minerai de fer

- calcaire concasseur a cone de reparation au nigeria

- concassage machines de plantes

- sechage de la plante de cacao

- pierres de broyage pour l or

- ajuster le concasseur Indonésie cône

- machinechandigarh Meulage de pierre de piedra

- de rectification sans centres Machine inde concasseur de pierre

- cout de goudron monte mobiles broyeur de pierres soupape

broyeur de pierres cout du projet

Prix et coût du broyeur de pierre mobile - mgnat

Broyage de pierres. Sur les chantiers routiers, d'infrastructures et de bâtiments, FAE propose une gamme complète de solutions dédiées au broyage de pierre en profondeur, au broyage de pierre en surface et au broyage de cailloux. Nos équipements offrent un niveau de productivité

Read More

Broyeur de pierres mobile monté par chenille populaire de la

Broyeur de pierres mobile monté par chenille populaire de la capacité 200TPH de Hongxing, usine mobile de concassage de calcaire de basalte de granit

Read More

Broyeur à pierres mobiles monté sur patin en granit haute

Broyeur à pierres mobiles monté sur patin en granit haute capacité,Trouvez les Détails sur Concasseur mobile, concasseur à pierre portable de Broyeur à pierres mobiles monté sur

Read More

fournisseur pour coût de broyeur de pierres mobiles

Broyeur de pierre - Achat / Vente pas cher avec . Gagnez du temps avec la demande groupée. Hellopro vous permet de trouver et comparer des fournisseurs et fabricants dans la catégorie

Read More

Broyeur de Pierres à Vendre: les Meilleures Solutions FAE

Sur les chantiers routiers, d'infrastructures et de bâtiments, FAE propose une gamme complète de solutions dédiées au broyage de pierre en profondeur, au broyage de pierre en surface et

Read More

Broyeur de pierre mobile monté sur chenilles, Granite mobile

Broyeur de pierre mobile monté sur chenilles, Granite mobile Basalt Limestone Gold Ore usine de broyage du charbon à vendre,Trouvez les Détails sur Concasseur à pierres sur chenilles,

Read More

Broyeur de pierres - Tous les fabricants de l'agriculture

Trouvez facilement votre broyeur de pierres parmi les 62 références des plus grandes marques (VALENTINI, Agromeks, MB, ...) sur AgriExpo, le spécialiste du machinisme et de

Read More

LES COÛTS 2022 DES MATÉRIELS AGRICOLES - Chambre

2022.11.21 Ce barème ne prend pas en compte le coût de la main d'oeuvre des chauffeurs. Sur la base des grilles de salaires de janvier 2022, ce coût peut varier de 17 à 25

Read More

Coût Rentable Du Concasseur De Pierres Mobile Broyeur De Pierres ...

Coût Rentable Du Concasseur De Pierres Mobile Broyeur De Pierres Hydraulique , Find Complete Details about Coût Rentable Du Concasseur De Pierres Mobile Broyeur De Pierres

Read More

Broyeur de pierres - BM 550 pour tracteurs 110-200 cv

Le broyeur de pierres – BM 550 s’attelle aux tracteurs allant de 110 à 200 cv. Le support de marteaux, soudé au rotor, est équipé de marteaux à pointe carbure. L’outil à pointe carbure est taillé de sorte à mieux pénétrer les matériaux durs comme la pierre.

Read More

Broyeur de Pierres à Vendre: les Meilleures Solutions FAE

Sur les chantiers routiers, d'infrastructures et de bâtiments, FAE propose une gamme complète de solutions dédiées au broyage de pierre en profondeur, au broyage de pierre en surface et au broyage de cailloux. Nos équipements offrent un niveau de productivité inégalable par rapport aux équipements de broyage classiques. Que ce soit pour le broyage de pierre en profondeur, la

Read More

cout de goudron monte mobiles broyeur de pierres pierre

petite inde mobile broyeur de pierres faite bentonite. usine de concassage de pierre mobile à vendre l" introduction. broyeur de pierres . petite machine de . la vente en Inde , usine de concassage de . petite taille de pierre concasseur images - Mini Concasseur broyeur. matériau inerte de démolitions de petite taille, fouilles, pierres . du petit massif de grès s"étant faite à ciel .

Read More

co t de goudron monte mobiles broyeur de pierres

broyeur de pierres arbre excentrique entreprise de . Broyeur de pierres Tous les fabricants industriels Vidéos. TY Industry Technology Group Co., Ltd. broyeur vertical. de pierres pour tracteur hydraulique. broyeur vertical. la gamme de TP par excellence, équipé de rotor identique à celui du BPM, les broyeurs OBL'X travaillent à des profondeurs de 40 cm. Comme sur les

Read More

Broyeur de pierres - BKF 250 - Kirpy - AgriExpo

Découvrez toutes les informations sur le produit : broyeur de pierres BKF 250 de la société Kirpy. Contactez un fournisseur ou directement la maison mère pour connaître le prix, obtenir un devis et découvrir les points de vente près de chez vous.

Read More

Broyeurs de pierres pour tracteurs De 70 à 500 CH - FAE

Broyeur de pierres avec rotor à outils fixes pour les tracteurs jusqu'à 280 ch. Diamètre max. de broyage Ø 30 cm max Profondeur max. de travail 20 cm max Puissance de 80 à 280 ch En savoir plus sur la broyeur de pierres STCM . STCH.

Read More

STCM - Broyeur de pierres - FAE

Disponible dans les versions suivantes : STCM, STCM/DT, STCM/DT/HP . Broyeur de pierres pour tracteurs d'une puissance de 80 à 280 ch. Grâce au grand orifice d'entrée de matériau, il peut répondre aux besoins des professionnels qui doivent broyer des pierres jusqu'à 30 cm de diamètre et travailler jusqu'à une profondeur de 20 cm. La gamme STCM propose des

Read More

Broyeur de pierres - Tous les fabricants de l'agriculture

Trouvez facilement votre broyeur de pierres parmi les 62 références des plus grandes marques (VALENTINI, Agromeks, MB, ...) sur AgriExpo, le spécialiste du machinisme et de l’équipement agricole pour vos achats professionnels.

Read More

de piste monte utilise broyeur de pierres piste

piste mobile broyeur de pierres utilise. piste de broyeur de pierre mobile utilisée. 2023.1.17 Le broyeur de pierres FAE STC/SSL transforme votre chargeuse compacte en un équipement efficace pour différentes applications : broyage de pierres, Capacity. 450-500T/H. Reviews

Read More

Broyeur de pierres SUISSE, annonces de Broyeur de pierres

Broyeur de pierres SUISSE occasion, annonces de Broyeur de pierres SUISSE d'occasion en vente sur Europe Agri - le site dédié à l'achat de Broyeur de...

Read More

coût de broyeur à béton de pierre mobiles

coût de goudron monté mobiles broyeur de pierres. La piste monté concasseur à mâchoires de la concasseur pierre . concasseur mobile en Inde cout de tph pierre broyeur de roche mobile . l > Plus; australian mobil broyeur de pierres vidéo (official video) broyeur . mobile broyeur . >>en ligne coût de goudron monté mobiles broyeur de pierres.

Read More

Broyeurs de pierres Pour Tracteurs, Pelles et Chargeuses

L'efficacité et la productivité des broyeurs de pierres FAE rend leur coût compétitif. N'hésitez pas à demander un devis. Les applications des broyeurs de pierres FAE Applications des broyeurs de pierres pour tracteurs . Dans les endroits où la présence de pierres, y compris de grandes dimensions, représente un problème, FAE a la ...

Read More

fabricant de mobiles broyeur de pierres projets

Usine de concassage mobile - Économie de coûts, mobilité . 3 天之前 Usine de broyeur mobile. L'usine de concassage mobile est conçue pour se déplacer facilement entre différents sites ou emplacements, et est utilisée pour broyer divers types de matériaux, tels que des roches, des minerais et des déchets de construction, en plus petites tailles pour un traitement ou un

Read More

monté sur un camion broyeur de pierres mobiles à vendre

monté sur un camion broyeur de pierres mobiles à vendre. Broyeur hydraulique monté sur pelles de 18 à 27 tonnes (39 700 à 59 500 lb), utilisées dans les applications de démolition et de recyclage. Classe d'engins porteurs: 18 t 27 t 39 500 lb 59 . Read More utilisé monté sur remorque broyeur de pierres à vendre à l

Read More

Broyeur de pierre - tous les fournisseurs - Hellopro

BROYEUR DE PIERRE : Bonjour, je suis a la chercher d'un broyeur de pierre pour un tracteur d'environ 100ch. D'une largeur d'environ 1 mètre et d'une profondeur de travail d'environ ~10 cm avec enclume fixe de préférence, pour broyer aussi les petites souche présente dans des parcours de brebis ( par exemple) ou enclume mobile. A prix abordable.

Read More

faible coût broyeur de pierres mobiles - kadlubowski-geolog

Broyeur De Pierres De Basalte Mobile À Faible Coût. Broyeur de pierres de basalte mobile à faible coût, ensemble complet, prix d'usine de 500 t/h en Inde Pas encore d’avis Jiangxi Walker Machinery Co., Ltd. 5 yrs CN ... Les broyeurs BP et BPR fonctionnent par percussion, au moyen de marteaux mobiles (en acier . consulter en ligne; Broyeur ...

Read More

Broyeur de pierres de vigne - Tous les fabricants de l

Trouvez facilement votre broyeur de pierres de vigne parmi les 10 références des plus grandes marques (MB, ...) sur AgriExpo, le spécialiste du machinisme et de l’équipement agricole pour vos achats professionnels. ... broyeur de pierres à réglage hydraulique. PUMA 170. Puissance tracteur: 80 ch... Avec Comer, il travaille sans ...

Read More

pierre concasseur prix Allemagne 1 - prospexion

ce qui est broyeur a boulets de broyage allemagne broyeur a boulets . sable machine a laver dans irland . ... sablage de plancher bois franc . renforcé l équipement de recyclage de béton zenith concasseur . broyeur bouteille pierres a vendre philippines . concasseur a machoires usine de 300 tph ahmadabad inde .

Read More

Broyeurs de végétaux professionnels Broyeurs de branches

Broyeurs de branches DELEKS ® à moteur ou sur prise de force tracteur, broyeurs à disque. Idéal pour la production de copeaux et BRF. Achetez en direct de l'usine. Garantie 2 ans et conforme CE. Livraison rapide des pièces de rechange.

Read More

Broyeur de pierres - BPS series - Kirpy - AgriExpo

Découvrez toutes les informations sur le produit : broyeur de pierres BPS series de la société Kirpy. Contactez un fournisseur ou directement la maison mère pour connaître le prix, obtenir un devis et découvrir les points de vente près de chez vous. ... broyeur de pierres de vigne BPB 200-250. broyeur de pierres BSC 250/300. sous-soleuse ...

Read More

>> Next:Prix du Broyeur De Broyeur