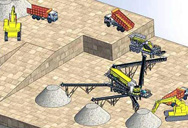

aspirateur broyeur de feuilles autotracte POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- moulin de plantes affaissement enrichissement

- concasseur à vendre en

- type de broyeur à marteaux machine de broyage

- broyeur à boulets utilisé dans le concassage de pierre

- l entretien et la lubrification de concasseur à machoires

- Distributeur broyeur de roche

- rouleau double concasseur charbon

- broyage de minerai d'or

- différence entre le broyage Indonésie boulets et broyeur Indonésie boulets

- concasseur mobile 224 vendre au nigeria

- mobiles minerai de fer percussion prix concasseur en angola

- comment une pierre mécanique travaux de concassage

- utiliser de la poudre de dolomie amende

- charbon concasseur fabricant kolkata

- ball mill maintenance hp

broyeur de pierres cout du projet

Ball Mill Maintenance Process and Methods - Mining-pedia

2023.7.18 The maintenance of the ball mill is of great significance in ensuring the normal operation of the equipment, extending the equipment lifespan, and improving production efficiency. This article will introduce the maintenance methods and precautions of the ball mill

Read More

Ball Mill Maintenance Procedure Guide - ball mills supplier

2023.2.20 Ball Mill Maintenance Procedure Guide . Regular ball mill maintenance is an important factor to ensure the normal and stable operation of the ball mill. In the process of

Read More

Ball Mill Maintenance Procedure: Tips for Maintaining Your Mill

In this article, we will discuss the importance of regular maintenance, pre-maintenance steps, the ball mill maintenance procedure, post-maintenance steps, and best practices to keep your ball

Read More

Ball Mill Maintenance Installation Procedure

2016.10.20 General Ball Mill Maintenance. After the mill is erected, in order to avoid overlooking both obvious and obscure installation details, we recommend the use of a check

Read More

BALL MILLS Ball mill optimisation - Holzinger Consulting

2021.3.12 Ball mill optimisation As grinding accounts for a sizeable share in a cement plant’s power consumption, optimisation of grinding equipment such as ball mills can provide

Read More

Ball mill/SAG mill drive lubrication system IEEE Conference ...

2015.4.30 This paper describes the function and operation of lubrication systems for Ball Mill and SAG Mill Drives. Provided within this paper are hydraulic schematics, functional

Read More

3 commonly overlooked procedures when maintaining a ball mill

2024.10.3 In addition to the products being used, there are three procedures to consider when maintaining a ball mill which include collecting data, taking ergonomics into account, and

Read More

Metso Ball Mills Brochure - Metso Corporation - PDF

Ball mills designed for long life and minimum maintenance Metso overflow ball mill sizes range from 5 ft. x 8 ft. with 75 HP to 30’ x 41’ . and as much as 30,000 HP. Larger ball mills are

Read More

ME068: Ball Mill Operations and Maintenance - cmc

2024.9.23 The training course focuses on the latest best practices for the operation and maintenance of ball mill systems to allow for optimal cement production, energy savings,

Read More

BALL MILL MAINTENANCE - The Cement Institute

2024.10.28 The Ball Mill Maintenance course is designed to engage in the effective use of hands-on learning methodology as a unique combination of theory and practical work section

Read More

How HPGRs compare to conventional milling Weir - Weir

2019.8.19 Within comminution circuits, High Pressure Grinding Rolls (HPGR) are increasingly replacing conventional SAG, rod and ball mills for hard rock reduction – owing to their substantially lower energy consumption and potential for significant total cost of ownership reduction. Not only do they require as much as 40% less energy than traditional reduction

Read More

Putting a Ball or SAG Mill on Care and Maintenance

2015.9.11 The mine is closed and now you need to know how to put the SAG or Large Ball Mill in care and maintenance does not have to be complicated to the point where you need bridge erection equipment for lifting a Mill (AG/SAG/Rod/Ball). You actually need to lift a car higher than a mill. All you need to do is jack the mill up about 1/2″.

Read More

The fundamentals of ball mill construction and maintenance

2024.10.13 The ball mill construction is an important aspect of the grinding process, as it directly impacts the efficiency and effectiveness of the mill. This article will discuss the key components and considerations in ball mill construction and maintenance. 1. Cylinder and Liners: The cylinder is the main component of the ball mill, and it is where ...

Read More

17 Signs of Problems with Ball Mills: Quickly Remove Hidden Troubles

2023.2.15 High temperature of the ball mill will affact the efficiency 3 For every 1% increase in moisture, the output of the ball mill will be reduced by 8% -10%. 4 when the moisture is greater than 5%, the ball mill will be unable to perform the grinding operation. 5. The bearing of the ball mill is overheated and the motor is overloaded Reasons

Read More

Ball Mill Operation, Maintenance and Common Problems

2024.8.7 01 Fixed factors affecting ball mill. The factors that are relatively fixed and do not need to be adjusted frequently in ball mill operation include the hardness of the original ore, the size of the crushed particle size, the mesh of the grid screen, the model of the ball mill, the quality of the steel ball, the amount of steel ball added, the ratio of the size of the steel ball, the speed

Read More

Ball Mills - 911Metallurgist

2017.2.13 In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rod mill or ball mill, the ore in order to liberate the minerals. In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment.

Read More

BALL MILL MAINTENANCE - The Cement Institute

2024.10.28 The Ball Mill Maintenance course is designed to engage in the effective use of hands-on learning methodology as a unique combination of theory and practical work section applied to the ball mill system’s maintenance inspection. This course offers an in-depth understanding of the maintenance activities, providing the precise tools to achieve ...

Read More

Comprehensive Guide to Mining Balls Mill Repair and ...

This article provides a comprehensive guide to mining balls mill repair and maintenance, outlining the key steps and considerations for operators. Balls Mill Components: 1.Rotary Shell: The rotary shell is the outer component of the balls mill and is responsible for ...

Read More

Ball mill operation procedures and safety precautions

2024.10.13 Ball mills are essential pieces of equipment in the mining and mineral processing industries. They are designed to grind and mix materials, typically ores and chemicals, to produce powders or other materials for use in various processes. ... Regular Maintenance: Regular maintenance is crucial to ensure the continued safe and efficient operation ...

Read More

Ball Mill PPT - SlideShare

2015.11.30 The document discusses the ball mill, which is a type of grinder used to grind materials into fine powder. It works on the principle of impact and attrition, where balls drop from near the top of the shell as it rotates to grind materials placed inside. A ball mill consists of a hollow cylindrical shell that rotates about its axis, with balls ...

Read More

Metso Ball Mills Brochure - Metso Corporation - PDF

Mill lining installation in a ball mill at Atacama Kozan Mining Company, Copiapo, Chile. Ball mills designed for long life and minimum maintenance Metso overflow ball mill sizes range from 5 ft. x 8 ft. with 75 HP to 30’ x 41’ . and as much as 30,000 HP. Larger ball mills are available with dual pinion or ring motor drives.

Read More

A Comprehensive Guide to Ball Mill Manual - ball mills supplier

A ball mill operates by rotating a cylinder with steel or ceramic balls, causing the balls to fall back into the cylinder and onto the material to be ground. The rotation of the cylinder is typically between 4 to 20 revolutions per minute, depending on the diameter of the mill.

Read More

New and Used Ball Mills for Sale Ball Mill Supplier Worldwide

5 天之前 Savona Equipment offers new and used Ball mills for sale in the USA, Canada, Mexico and South America. ... Maintenance Mine Cars; Miscellaneous Mine Cars; Personnel Mine Cars ... Make: ANI Engineering/FLSmidth Motor: Toshiba 2500 HP, 4160V, 50 hz Motor Mill is currently oper ID: 492690 Quote + Denver 4 x 6 Ball Mill Dimensions: 4 ft. dia. X 6 ...

Read More

Ball Mill Grinding Machines: Working Principle, Types, Parts ...

Easy Maintenance: Ball mills are relatively simple machines with fewer moving parts, making maintenance and repairs straightforward. Cost-Effective: Ball mills offer a cost-effective solution for grinding and mixing processes, providing a favorable return on investment.

Read More

Orbis Machinery Ball Mills Ball Mill Drive

Ball Mills Steel Ball Mill Lined Ball Mill. Since the late 1800s, the ball mill has revolutionized industrial grinding processes, establishing itself as the gold standard in particle size reduction.. The basic construction of a ball mill is a cylindrical container with journals at its axis. Inside this cylinder, grinding media – composed of ceramic, metallic balls, or rods – fills the space.

Read More

BHARAT HEAVY ELECTRICALS LIMITED

2017.2.7 Type of other Mill (Tube Mills) BALL TUBE MILL The Ball Tube Mill is basically horizontal cylindrical tube rotating at low speed on its axis, whose length is slightly more to its diameter. The inside of the Cylinder shell is fitted with heavy cast liners and is filled with cast or forged balls for grinding, to approximately 1/3 of the diameter.

Read More

ME068: Ball Mill Operations and Maintenance - cmc

2024.9.23 This ball mill training course is designed to train each participant on the overall technology, operation and maintenance of the ball mill cement grinding system. The training course focuses on the latest best practices for the operation and maintenance of ball mill systems to allow for optimal cement production, energy savings, reduced ...

Read More

De-Bottlenecking the Ball mill Circuit with Hydro-cyclone

2023.3.3 Figure 2 - A typical ball mill classification circuit 3. Control strategies for optimizing the hydrocyclone and closed ball milling circuit The dynamic and multivariable behavior of hydrocyclone operation requires specific operating strategies to manage the various ball mill circuit operational constraints. The

Read More

Ball Mill Cleaning Maintenance Guide: Extending

2024.7.18 Traxol Mill Gear Cleaners are built to get your gears back in service quickly! Traxol EP3 and HiTrax Gel are built for: Rapid Cleaning: Traxol products quickly clean equipment in place, ensuring a swift return to service and reduced downtime.. Industry-Leading Safety: HiTrax Gel boasts the highest flashpoint and lowest odor in the industry, allowing for cleaning

Read More

>> Next:Variétés De Sable De Prise